Curtain is a piece of cloth or other material, sometimes arranged so that it can be drawn up or sideway, hanged for decoration as at a window, or cover conceal.

There is manual method used to open and close the curtain in Tanzania residential houses or commercial or institute houses and industrial such as remote controlled system and manual method. The common method used is manual method ( by using hands.)

PROBLEM OF STATEMENT

The existing method of opening and closing curtains at ASA LOUNGE is manual method which involve usage of hands for opening and closing of curtains.

The leads to more time consuming, energy consuming and breaking of hooks and hangers which require frequently replacement and hence increase running cost.

OBJECTIVES OF THE PROJECT

MAIN OBJECTIVE

The main objective of the project is time consuming, energy consuming, to saves breaking of hooks and hangers by automatic electronic control circuit for opening and closing of the curtain.

SPECIFIC OBJECTIVE

Design the required circuit.

Select proper components for the circuit.

Build the prototype.

To test the prototype.

METHODOLOGY

The following are the methodologies to be followed to accomplish the project

Literature review

Data collection

Data analysis

Design of an electronic circuit

Build prototype

Testing prototype

Report writing

SIGNIFICANCES OF THE PROJECT

Reduce unnecessary operating cost.

Reduce operator’s energy.

Saves time.

LITERATURE REVIEW

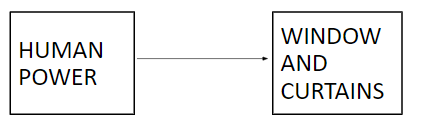

The mode operation of both existing and proposed system are illustrated below

EXISTING SYSTEM

The operation of the existing system is manual type which consists of two blocks which are:-

Human power

Window and curtain

BLOCK DIAGRAM OF EXISTING SYSTEM

OPERATION OF EXISTING SYSTEM

HUMAN POWER

Here is where by user apply the force for opening and closing the curtains.

WINDOW AND CURTAIN

Here is where by the controlled curtain has been inserted.

PROPOSED SYSTEM

In order to solve the stated problem an electronic control circuit has proposed

The circuit will consist of six main blocks which are:-

1. 1~supply

2. AC/DC converter

3. Control circuit

4. Motor starter

5. Motor

6. Window and curtain

BLOCK DIAGRAM OF PROPOSED SYSTEM

OPERATION OF THE PROPOSED SYSTEM

POSITION OF DC MOTOR

DATA COLLECTION

PROPOSED CIRCUIT

OPERATION OF THE PROPOSED CIRCUIT

LDR is the sensor which used to sense the light and darkness after sense send the signal to the first timer(555 timer).This timer used to regulate the signal either in higher signal or lower signal. If the signal is high motor run forward and if the signal is low motor run reverse. In decode counter this is digital integrated circuit used to receive the signal from the first timer and to direct that signal either in second timer which used to run the motor forward or third timer which used to run motor reverse. Signal which used to trigger the second timer must be high during motor run forward LED(blue) indicate and if the signal is low the third timer is triggered and LED(green) indicate.

Function of D4 & D5 is used to limit the signal from the decode counter. Limit switch is used to switched OFF the motor when open or closed the curtain. If the motor is OFF state LED(red) indicate.

DATA ANALYSIS

Motor analysis

Power of motor= Work done/ Time taken

=Force*Distance / Time taken

But Force = Mass*Acceleration due to gravity

Force=1kg*9.8m/sec2

9.8N

Power of motor = 9.8 * 1.315 / 5Sec

=2.57W

According to manufacture their is no motor of 2.57W Also, must be to approximate to 3W

Therefore the horse power of Motor

1hp = 746W

? = 3W

3W/ 746W

0.00402HP

The standard horse power is 1HP

Transformer analysis

The supply available is 220-240VAC, 50Hz as the load which is supplied by transformer is 12VDC also the current needed by the load is 30mA. Hence transformer employed is 230/12V 800mA.

Primary power supply is 220-240V 50Hz, step down transformer will be used to step down the primary supply up to 12V 50Hz which will be rectified by a full wave bridge rectifier. Diodes used in the full wave bridge rectifier are made of silicon which has a constant voltage drop of 0.7V each.

Total drop in the bridge = 0.7 V x 2

= 1.4V

Vm = 12V x √2

= 16.97V ≈17V

Vdc = 2Vm

╥

= 2×16.97

╥

= 10.8V

Voltage output at the bridge = 10.8V – 1.4V

= 9.4V

Bridge rectifier analysis

Bridge rectifier is the circuit made of diodes for converting AC voltages to DC voltages, both positive and negative waveforms of AC voltage is converted to one direction. So only flow in one direction and do not alternate.

Since the peak voltage across the transformer secondary is 17V the total peak inverse voltage of the diode bridge is about (4*17) i.e 68V so I have to settle down for diodes with PIV rating of 100V

Resistance Analysis of limit Current

From the data sheet of the resistors

Maximum current required is 0.1A and since the supply of the system is 12V then the values of resistance to limit current flow is given by:-

T=1.1xR2xC1

Time delay of Timer no. 1 is 330s

Let C1=10µF

R2=330×1.1(10×10-6)

R2=500kΩ

R1,R3,R4 Are any resistors which are used to limit excess input current

From manufacturing data sheet Decode Counter (CD 4017).This is Digital integrated circuit from input voltage 12VDC voltage drop is (1-2)VDC . Also the output voltage(Vo) of Decode Counter is 10VDC and LED voltage is 2V and maximum current(Imax) 20mA.

From

Vo=VLED+VR

10=2+(20×10-3)R5

R5=5Ω

According to the same LED voltage and the output voltage always all resistors R5,R6,R7 are the same value.

According to manufacturing data sheet capacitor (C2) is constant value(0.01-10)nF

555timer Analysis

A commonly available NE555 timer can used since it operates at a dc voltage of 10V at a current of 10mA and supplies the input to the Decode counter either in higher signal or low signal and the output of digital integrated circuit (decode counter) is used to triggering the Timer one appropriate pulse by running the motor forward and timer two to running the motor reverse.

Analysis of power Diode

Diode(D4) and diode (D5) are used to control the signal received from the output of decode counter diode are categorized in many category such as IN400,IN4002 and IN4007, suggest use power diode IN400 because of high power for control signal than others.

CONCLUSION

In this report, it was demonstrated that design of an automatic electronic circuit, which used to open and close the curtains. The circuit was operated hence the main and specific objectives were met.

RECOMMENDATIONS

Any person who is willingly to modify and improve the circuit is allowed to do so, by either employing the use of battery in case when the power supply is OFF to ensure the continuity of the operation.