ATCB- Afri-tea & Coffee blenders (1963) limited, is the company situated at Bandari load, opposite gate number 4 of the main port at Dar es salaam.

This company deals with packing of the tea and coffee for the consumable purposes.

The project is going to be beneficial for the company and whole society who faces the alike problem.

This project is basically based on designing the system which will help in sorting of the improper weighed tins, rather than sorting them manually as it is performed recently.

PROBLEM STATEMENT

Problem which is to be delt with this project is the time wastage on sorting the tins, and having number of labours to perform this function.

So due to this problem, The designing of isolation system will help to sort all improper weighed tins hence having minimum time wasted.

SIGNIFICANCE OF THE PROJECT

Under the success of this project, less time will be consumed in isolating the tins.

Less man power will be employed, hence less financial resources utilized.

METHODOLOGY

Literature review

Data collection

Data analysis

Designing of circuit

Build the prototype

Testing the prototype

Report writing

LITERATURE REVIEW

This section includes existing system and proposed system.

The Existing System

Proposed system

Other components reviewed;

Single acting cylinders

PNEUMATIC SOLENOID VALVES

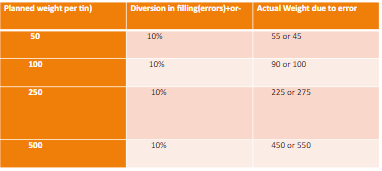

DATA COLLECTION

The data collected in my project were obtained as follows

Data analysis and design

The following is the proposed circuit for the designed system.

A/.Power supply

The control unit requires a 5V at 40 mA in the operation in this project.

The power consumption is thus:

Power = I x V

5V x 40 mA= 200 mW

B/. Servo motor

The servo operates at averaged 4.8 to 5v

C/. The load cell amplifier

The amplifier selected operates at 5V to maximum of 15V.

LOAD CELL TRANSDUCER

The load cell used in this project as proposed is supposed to have the capability of detecting the maximum of 1 kg.

The output electrical signal for a load cell is relatively low to be detected to a control unit which requires an input voltage of 5V and above.

Output signal for a load cell is 10 mV for 6 kg.

Now for the maximum weight to be measured in this project which is 1 Kg, thus

Since;

10 mV responds for 6 kg,

For 1kg = 10 mV/6kg= 1.67mV

For unit detection control the signal has to be amplified to 5V.

Thus,

The amplification factor= input to control unit/ output of a load cell

=5V/1.67mV=2994

The need for an amplifier to amplifier the signal to that extent

Gain = (Rf /R2) +1

Setting Rf=1MΩ

Gain=2994

R2=Rf/Gain= 1MΩ/2993

R2=334Ω (330Ω standard value)

Conclusion.

The design has been successfully completed, and the demonstrative prototype has been successfully archived by employing ultrasonic sensor which detects distance instead of weight .

Recommendation

The obtaining of materials have been a great challenge especially in implementing the prototype. However the designing idea was based on pneumatics but after carrying out some studies, the design has been shifted from Pneumatics to Savor motor implementation.

Hence it is recommended that for the development of this projected idea one has to be aware on cost as well as trying to search for materials from abroad markets instead of basing only on local markets.